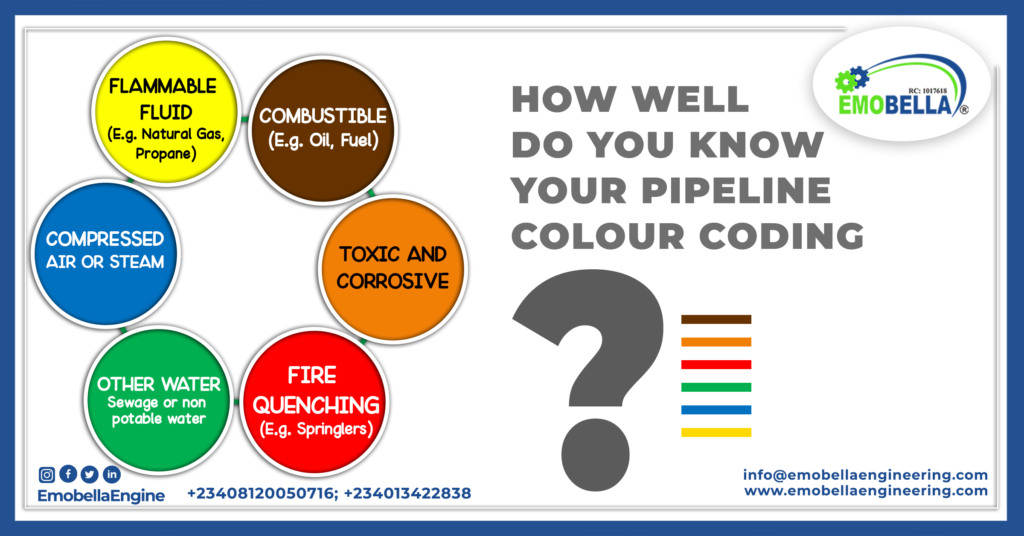

Piping systems are colour-coded to help identify the contents of the pipes and to assist maintenance and emergency personnel in identifying the correct lines. Different colours are used to indicate different types of fluids or gases that are being transported through the pipes. Colour coding of piping systems is an important safety measure that is widely used in various industries, including chemical processing, oil and gas, power generation, and pharmaceuticals, among others. It helps operators, maintenance personnel, and emergency responders to quickly identify the contents of the pipes and take appropriate steps when necessary.

The American National Standards Institute (ANSI) has established a standard for colour coding of piping systems, known as ANSI/ASME A13.1. This standard provides guidelines for the use of colours and labels for identifying the contents of pipes and piping systems. It includes a colour code chart that specifies the colours to be used for different types of fluids, such as water, steam, gases, and chemicals, as well as for different types of hazards, such as fire, corrosives, and radiation.

Colour coding of piping systems is an important safety measure that helps to prevent accidents, protect workers and the environment, and ensure efficient operation of industrial facilities. There are several benefits of pipe colour coding in a piping system. Here is a few importance; and benefits of colour coding:

1. Improved Safety: Pipe colour coding helps to improve safety by providing a visual cue to workers and emergency responders about the contents and hazards associated with the pipes. In an emergency situation, such as a leak or spill, responders can quickly identify the contents of the pipes and take appropriate action to contain the situation.

2. Compliance: Many industries are required by law to use colour coding to identify the contents of piping systems. Compliance with these regulations is essential to avoid fines and penalties, as well as to maintain a safe and compliant workplace.

3. Efficiency: Colour coding can help to improve the efficiency of operations by making it easier for workers to identify the correct pipes and components. This can save time and reduce the risk of errors and accidents.

4. Standardization: The use of standardized colour codes ensures consistency across different facilities and industries. This makes it easier for workers to move between jobs and industries without needing to learn new colour codes.

5. Communication: Colour coding can also serve as a communication tool, allowing workers to easily communicate information about the contents of the pipes to others. For example, a worker could say “Follow the red pipe” to direct someone to a specific location.

6. Prevents Cross-Contamination: Colour coding helps to prevent cross-contamination by ensuring that pipes carrying different fluids or gases are easily identifiable. This can help to prevent accidents and contamination of the environment.

Overall, pipe colour coding is an important safety measure that should be implemented in all industries where pipes are used to transport fluids or gases. By following industry standards and guidelines, companies can ensure that their piping systems are properly identified, and that workers and emergency responders can quickly and easily identify the contents and hazards associated with the pipes.