Introduction:

In the world of industrial operations, where precision, safety, and efficiency are non-negotiable, pipeline colour coding stands out as a fundamental safety practice. Far beyond being a mere visual aid, it is a globally recognized standard that plays a critical role in preventing accidents, reducing confusion, and promoting seamless operations across facilities.

Pipelines are the veins of any mechanical or electrical engineering system—they transport essential fluids, gases, and chemicals that power processes in manufacturing plants, oil and gas refineries, power stations, and utility services. Without clear and standardized identification, these pipelines can become silent threats, leading to misjudgements, maintenance errors, or even life-threatening incidents.

That’s where pipeline colour coding comes in. By using specific colours to identify the contents and functions of different pipelines, companies can ensure that every employee, from field technicians to emergency responders, understands exactly what flows through each pipe and how to interact with it safely.

Whether you’re an engineer, a health and safety officer, a facility supervisor, or someone keen on industrial best practices, understanding how pipeline colour coding works is essential. Not only does it enhance workplace safety, but it also ensures regulatory compliance, supports environmental responsibility, and improves overall efficiency within your operations.

In this comprehensive guide, we’ll dive into the principles, international standards (like ISO 20560 and BS1710), practical applications, and key benefits of pipeline colour coding. You’ll also discover how adopting this simple, yet powerful system can significantly elevate safety and performance in your facility, no matter your industry.

Stay Tuned!!

Why Pipeline Colour Coding Is Important:

Pipeline colour coding refers to the systematic use of specific colours to identify the contents and function of different pipes within a facility. These colours help in:

1. Enhances Workplace Safety

Firstly, colour coding significantly reduces confusion during routine operations, maintenance, or emergencies. When pipes are clearly labelled with standard colours, workers can quickly identify the contents and associated hazards—whether it’s flammable gas, high-pressure steam, or potable water.

As a result, this visual communication system minimizes the risk of accidental exposure, leaks, or incorrect handling of materials. It also enables emergency responders to act swiftly and appropriately, especially during high-stress scenarios like chemical spills or fire outbreaks.

2. Improves Operational Efficiency

In addition to safety, pipeline colour coding improves how smoothly operations run. Engineers, technicians, and maintenance teams spend less time inspecting or tracing pipelines because the necessary information is readily available at a glance.

Consequently, this leads to faster repairs, fewer delays, and minimal disruption to production processes. When time-sensitive tasks arise—such as shutting down a leaking valve or replacing a corroded section—clear pipeline identification can make all the difference.

3. Ensures Regulatory Compliance

Moreover, using a standardized colour-coding system helps organizations stay compliant with international safety and engineering regulations. Standards like ISO 20560, BS1710, and even local HSE guidelines require proper labelling of industrial pipelines.

Failure to comply with these regulations can result in safety violations, legal penalties, or failed audits. Therefore, implementing colour coding is not just a best practice—it is often a legal requirement for certified and safety-conscious engineering firms.

- Preventing accidents

- Streamlining maintenance

- Supporting compliance with health and safety regulations

- Helping emergency responders take quick and correct actions

It’s a crucial part of industrial safety practices and engineering project planning.

Why Pipeline Colour Coding Is Important

Understanding the importance of pipeline colour coding is key to building safer and more efficient industrial environments. Below are the major benefits, each explained in detail:

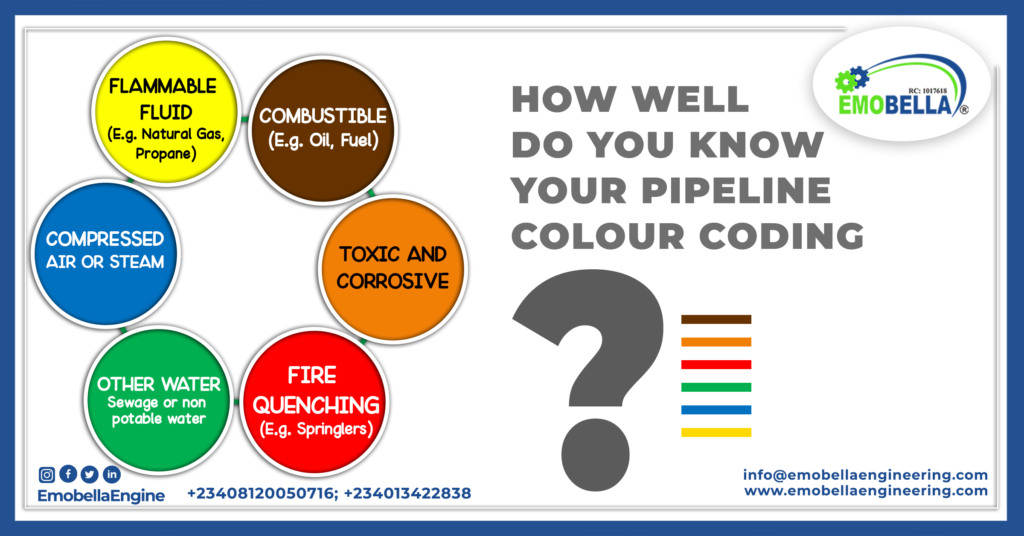

Common Industry Colour Codes and Their Meanings

📌 Note: Colour standards may vary depending on region or industry. Always cross-reference with your local regulations or project requirements.

| Colour | Indicates |

| Red | Firefighting water |

| Yellow | Flammable liquids or gases |

| Green | Potable water |

| Blue | Compressed air |

| Orange | Toxic or corrosive fluids |

| Brown | Fuel oils |

| Grey | Steam |

| Black | Waste or other hazardous materials |

These colours are often used in accordance with British Standards (BS1710), OSHA, and ISO 20560 pipeline identification guidelines.

Who Should Implement Pipeline Colour Coding?

- Industrial facility managers

- Mechanical and electrical engineers

- Health, Safety & Environment (HSE) officers

- Oil and gas contractors

- Water and wastewater treatment plants

- Engineering consultants

Emobella Engineering provides end-to-end support for pipeline installations, colour coding, inspections, and compliance certification.

Tips for Effective Pipeline Labelling

- Use durable, weather-resistant labels and markers.

- Ensure colour codes are consistent throughout the facility.

- Place labels at regular intervals and at pipe junctions.

- Incorporate arrow signs to indicate flow direction.

- Keep a pipeline identification chart in your control room.

Related Services – Emobella Engineering

- Metal Fabrication and Piping

- Instrumentation and Control

- Inspection | Testing and Certification

- Safety Valve Testing and Certification

- Procurement of Pipeline Safety Materials

- Calibration of process instrument

Visit to learn more about the colour coding

Read more:

- The Importance of Pipeline Integrity Testing

- How to Maintain Industrial Piping Systems

- Understanding Instrumentation and Process Calibration

Pipeline colour coding is a small yet powerful part of industrial safety and operational excellence. Whether you’re setting up a new plant or upgrading existing infrastructure, following proper pipeline identification practices can save lives, reduce errors, and boost compliance.

Need help with your pipeline colour coding system?

📞 Contact Emobella Engineering Nigeria Ltd for professional consultation, labelling, and inspection services today!