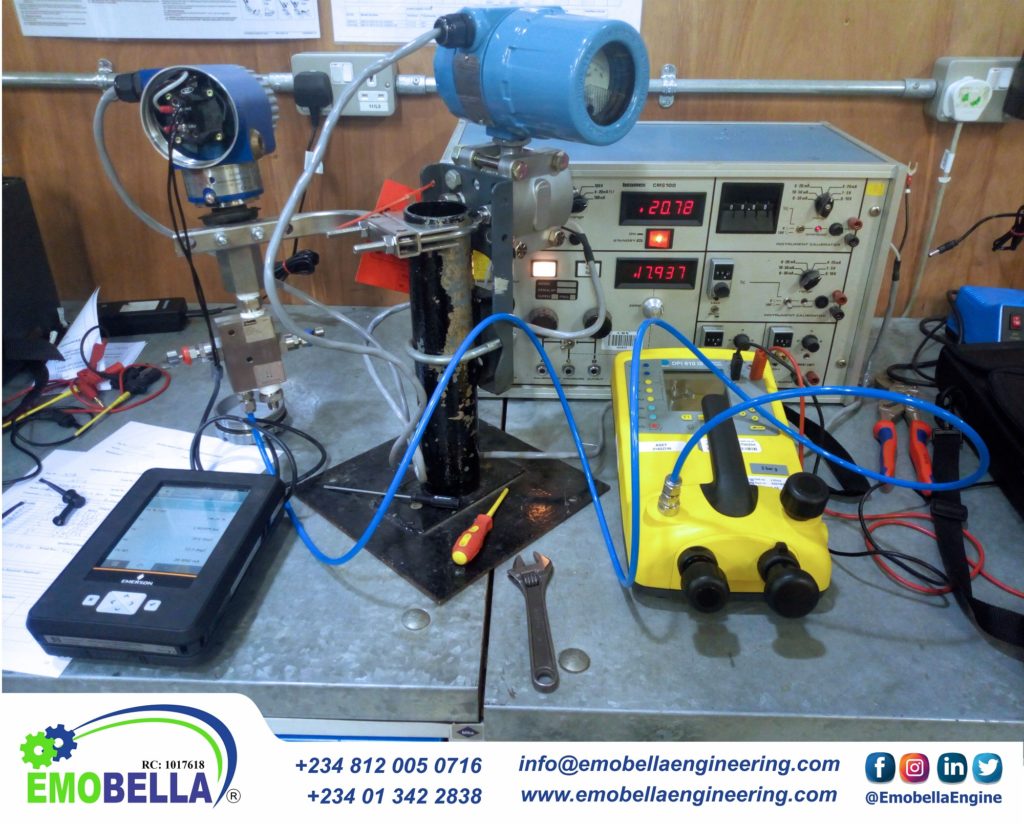

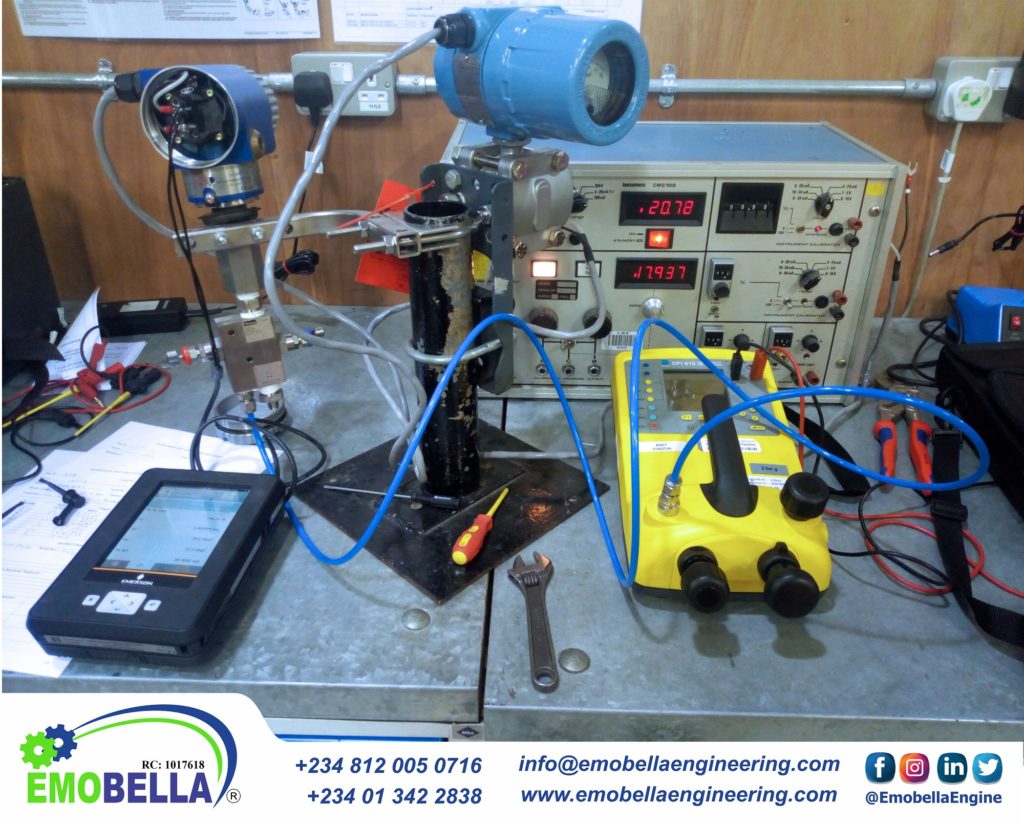

Process instruments such as temperature/pressure gauges, temperature/pressure transmitters, flow meters, etc. are subject to a variety of mechanical, chemical and thermal conditions. These conditions can lead to a reduction in your instrument accuracy and efficiency which the consequences can be as grave as plant explosion, reduction in quality and overall productivity.

Calibration can be performed using either a reference standard or a known value. This will help prolong the lifespan of the process instrument and maintain its high level of performance.

How often should you calibrate your process instrument?

The frequency of calibration depends on the type of process instrument and the prevailing conditions of where the instrument is being used.

• Calibration is required after any maintenance on the process instrument to ensure that the instrument is still conformed to the required calibration data.

• Recalibration should be carried out at least once a year. However, in some critical applications, the frequency of calibration will be greater such as recalibration once every six months.

• Recalibration should also be done when the process instrument was repaired after being faulty.

In summary, calibration is needed to make sure your process instrument is working correctly. You should also contact Emobella Engineering for your calibration services. We have a full-service ISO/IEC 17025:2017 standard that enables us to calibrate pressure, temperature, current, voltage, etc. A calibration test report and certificate are also provided after a calibration service has been carried out.

Contact us http://bit.ly/CONTACTEMOBELLA